Programmable Micro-Syringe Pump

spider-silk-hardware

assembly guide

Version 2.0

Pau Anta, 2023

MIT License

Introduction

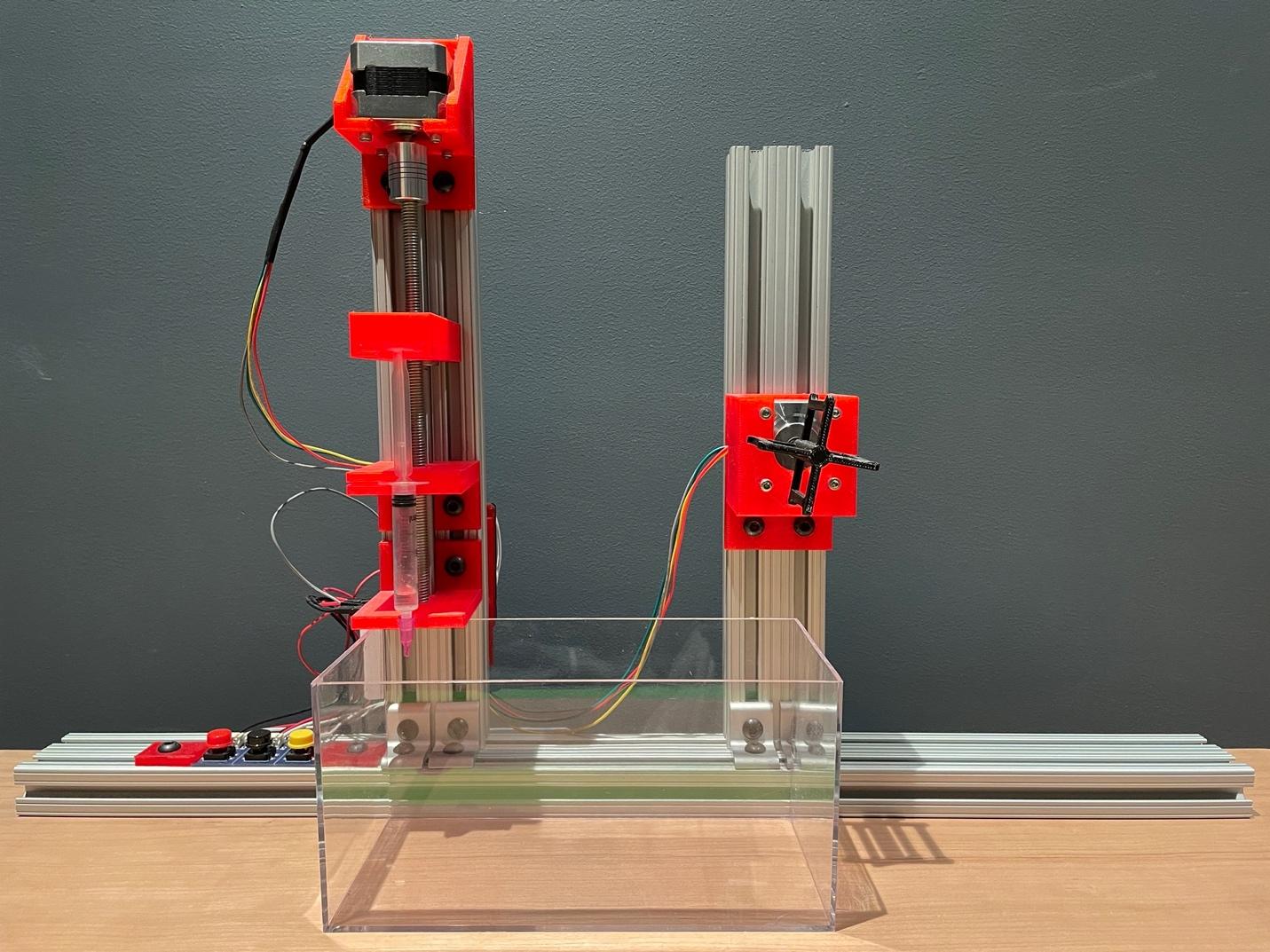

I built this programmable micro-syringe pump with a capture roller from scratch, as part of a bigger project to produce synthetic spider silk with electrical conductivity. I built it with inspiration from an open-source design found on GitHub: the OpenSyringePump developed by Naroom. While keeping most of the elements from the bill of materials of the OpenSyringePump, my micro-syringe pump was adapted to extrude the spidroins vertically into an acrylic case which contains a coagulation bath. A post-spinning capture roller was added to collect the spider silk as it was coagulated. The coding was done entirely from scratch with the intention of being able to extrude the dope at speeds as slow as 1 μL/min. Some parts were custom-designed and 3D printed, such as the cases that contain the motors and push buttons.

The reasons for developing this hardware (as opposed to buying a micro-syringe pump) were:

Parts (all listed in the bill of materials in GitHub)

1 316 Stainless Steel Threaded Rod

1 316 Stainless Steel Hex Nut

1 Carbon Steel Linear Motor Shaft (Beam Coupling)

1 Fixed Alignment Linear Ball Bearing

1 1 x 2 x 2 ft. Aluminum Extrusion

2 1 x 2 x 1 ft. Aluminum Extrusion

4 Silver corner brackets

12 Socket Cap Screw and T-Nut

1 5x8mm Motor Shaft Coupler

10 Stainless steel screws and nuts

1 Arduino Uno Rev3

1 Motor Shield

2 Stepper Motors NEMA17

1 Breadboard

3 STEMMA Wired Tactile Push-Buttons

2 Button holders (3D part)

1 Capture roll (3D part)

1 Motor H mount (3D part)

1 Motor V mount (3D part)

1 Rod mount syringe (3D part)

1 Rod mount barrel (3D part)

1 Rod mount plunger (3D part)

1 Arduino Uno Mount (3D part)

Tools

Allen keys set

Flat screwdriver 1/16”

Wire strippers

Jumper wires

Attach tiny breadboard to one side of a T-slotted extrusion frame of 1 ft. length.

Install the two 1 ft. T-slotted extrusion along the 2 ft. T-slotted extrusion, using two silver corner brackets for each one, and 2 T-nuts and bolts for each bracket.

Install Arduino Uno on the Arduino mount using 4 M2 screws.

Install the Motor Shield on the Arduino Uno microcontroller.

Install the Arduino Uno mount on the 1 ft. vertical T-slotted extrusion that has the attached tiny breadboard, using two T-nuts and bolts.

Install the stepper motor in the motor H mount using 4 M3 screws. Pass the wires through the lateral hole as you can see in the picture.

Install the motor H mount on the other vertical 1 ft. T-slotted extrusion on the opposite side, using 2 T-nuts and bolts, as shown in the images below.

Insert the capture roller in the shaft of the horizontal motor.

Install the rod mount barrel and rod mount plunge, the two parts that will hold the syringe, in the vertical 1 ft. T-slotted extrusion, using 2 T-nuts and bolts for each element. The distance between these two parts will depend on the size of your syringe.

The push buttons will allow you to control the micro-syringe pump (V motor). The buttons, from left to right, are start/stop, pull and push.

Install three push buttons in the 2 ft. T-slotted extrusion, on the left side of the vertical frame that holds the Arduino and rod mounts, using the button holders with T-nuts.

Install the stepper motor in the motor V mount using 4 M3 screws (pass the wires through the lateral hole as you can see in the picture). Assemble the stainless steel threaded rod with the motor shaft, using the beam coupling part.

Install the linear bolt bearing and the hex nut inside the two holes of the mount plunger, as you can see in the picture.

Turn the hex nut of the mount plunger around the threaded rod to the point that you see in the picture below (approximately).

Apply oil or Vaseline along the linear motion shaft and insert it through the linear ball bearing inside the mount plunger. Install the vertical motor in the same vertical 1 ft. T-slotted extrusion where the Arduino is installed.

Now, you are ready to use the micro-syringe pump with the capture roller.

Assembly Guide v2.0