E-Silk: Electrically Conductive Spider Silk

Pau Anta-Clusella, pauanta@icloud.com

https://www.pauanta.bio/e-silk

https://github.com/PauAntaBio/spider-silk-hardware

Washington DC.

Draft: August 2022

Introduction

Spider silk is a biomaterial with excellent physical properties such as high tensile strength, high stretchiness, and high toughness [1, 5, 7]. Because of the fierce nature of spiders, the current method of spider silk production involves producing recombinant spidroins in bacterial systems and spinning them into silk [2, 3, 8]. However, the use of denaturation during the purification and fiber formation of the spidroins leads to spider silk with dissatisfying mechanical properties [5].

Presented within is a novel application for synthetic spider silk: spider silk with electrical conductivity, which could be used in clothing to create circuits or expand the current applications of smart fabrics. Some examples include: stretch sensors, functional buttons, and circuitry that can activate a small device.

By taking advantage of genetic engineering techniques a recombinant spider silk protein was created and expressed in E. coli. This spidroin consists of a N-terminus from major ampullate (MaSP) silk with a repetitive region and C-terminus from minor ampullate silk (MiSP). Further, by adding a tetracysteine motif the spidroin should gain the ability to bind to gold (Au) nanoparticles via disulfide bonds [4]. Gold was chosen for its resistance to oxidation and electrical conductivity.

1

Design of Custom Protein

Spidroins vary in length and size but generally consist of three parts: a non-repetitive globular N terminus (NT), an extensive glycine- and alanine-rich repetitive region, and a nonrepetitive globular C terminus (CT) [3]. The NT subunits are bundles of 5 alpha helices; at pH levels above 7 they are monomeric, but dimerizes at pH levels below 6. The dimerization process consists of the alpha helices shifting to form a flat dimer interface, allowing the antiparallel subunits to combine [5]. The CT is a stable and soluble homodimer at pH levels greater than 6.5, but as the pH decreases to below 5.5 it destabilizes and loses its helical structure, instead forming β-sheet fibrils. Increased pCO2 (partial pressure of CO2) also aids in unfolding by interacting with partially hidden residues in the CT [5]. The CT’s transition into β-sheet fibrils produces nuclei that may induce the transformation of the repetitive region into β-sheet polymers [5].

The custom protein was largely based off of the synthetic spider silk developed by the 2019 Great Bay iGem team [3]. The NT domain of the custom spidroin is from the Euprosthenops Australis MaSp (Figure 1) due to its high solubility and pH sensitivity [3, 8] while the repetitive region and CT domain is from Araneus ventricosus MiSp. Since the repetitive region is very alanine and glycine rich, so much so that the epithelial cells of spider glands have abnormally large tRNA pools for the two amino acids [5], the spidroin only contained 2 repetitive regions. Otherwise, the E. coli may not have been able to express a high amount of the proteins. A GNS linker connected the various regions together while a 6His tag was used for Ni-NTA purification. A tetracysteine (TC) motif was added to the repetitive region to allow the spidroin to bind to Au nanoparticles.

2

Figure 1. Image of the N-terminus domain of the recombinant spidroin. In red is the GNS linker, in green is the homodimer NTD, in yellow is a protease cleavage site for Factor Xa (was never implemented), and in purple is the 6His Tag.

The TC motif is an encodable motif originally designed for the in vivo imaging of proteins. It consists of 2 cysteines followed by 2 non-cysteine residues followed by 2 more cysteines (Cys - Cys - X1 - X2 - Cys - Cys) [4, 6]. The thiols of the cysteines are intended to bind to biarsenical dyes which then fluoresce, but the TC motif could also be capable of binding to the surface molecules on Au nanoparticles via disulfide bonds. Moreover, by making the 2 middle amino acids proline and glycine, respectively, the TC motif forms a beta-hairpin structure that controls the orientation of the Au nanoparticles [4, 6].

3

DNA Sequence and Expression

The following sequence (Figure 2) encodes for the aforementioned spidroin with a NT domain from Euprosthenops Australis MaSp, a repetitive region and CT domain is from Araneus ventricosus MiSp, a TC Motif, a 6His Tag, and GNS linkers. The DNA plasmid was ordered from Atum (www.atum.bio) in an E.coli expression vector with an IPTG

inducible T5 promoter and a resistance to chloramphenicol.

Figure 2. DNA sequence of the custom spider silk protein

4

Due to the cost of synthesizing DNA, it was not possible to order two separate plasmids, one with and the other without the TC Motif, to compare the properties of normal synthetic spider silk and electrically conductive spider silk. Instead, a NgoMIV and BsaI cut site (highlighted in orange and green, respectively), were introduced on both sides of the TC motif to remove it via a double digest.

Nanoparticles

The reasoning for using Au nanoparticles is that gold resists oxidation and conducts electricity very well, and by binding it to spidroins, they should in theory gain electrical conductivity. A 120 ml sample of 100 ppm Au nanoparticle dispersion in water was ordered from US Research Nanomaterials, Inc (https://www.us-nano.com). The Au

nanoparticles were produced using 99.99% pure gold as raw materials and were 14 nm in diameter. They were stored at room temperature in dark conditions and were sonicated before each use in order to undo any aggregation of the nanoparticles.

Microsyringe Pump and Capture Roller

There are many techniques to spin spider silk, the easiest of which is wet spinning, in which the spidroins are dissolved in a chemical solution before entering a coagulation bath that removes the solvent and causes conformational changes [5, 7]. There are many combinations of solvents and coagulation baths, such as concentrated aqueous solution in saturated ammonium, hexafluoroisopropanol in methanol, hexafluoroacetone hydrate in methanol, and formic acid in methanol [7].

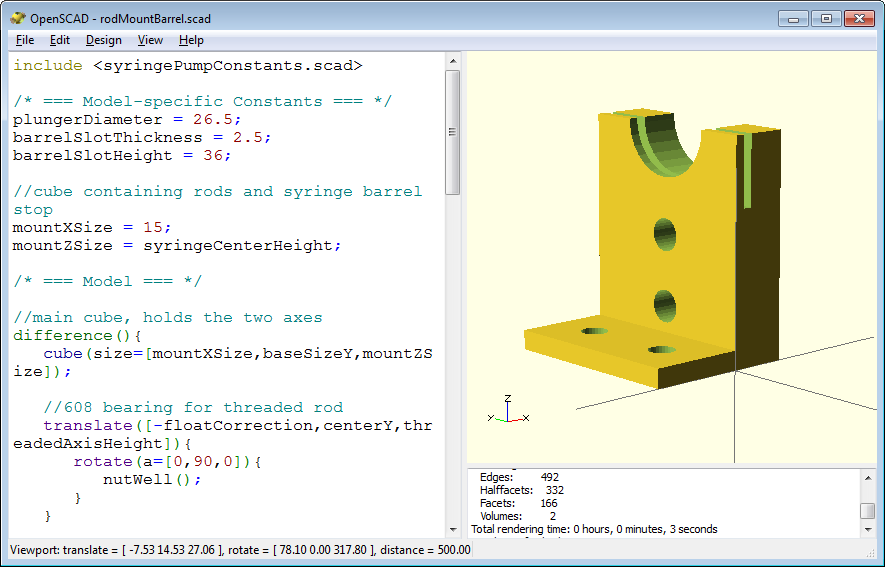

To perform wet spinning, a microsyringe pump was created from scratch based off of an open-source design found on GitHub [10]. While keeping the same bill of materials, the microsyringe pump was adapted to extrude the spidroins vertically (Figure 3A) into an acrylic case which contained the coagulation bath (Figure 3B). A post-spinning capture roller (Figure 3C) was added to collect the spider silk as it was coagulated. The coding was done entirely from scratch in Arduino IDE with the intention of being able to extrude the dope at speeds as slow as 1 µL/min. Some parts were custom designed and 3D

5

printed, such as the case that contained the motors, buttons, and the arduino motor shield. Because of the microsyringe pump’s design, shear force aided in the coagulation process of the spidroins [5, 7, 8].

A

C

B

Figure 3. Microsyringe Pump: A) Stepper motor that pushes the syringe at the desired flow rate; B) Coagulation bath where the spidroins will be pushed into. This will be filled with a chemical such as isopropanol; and C) Post-spinning roller that will collect spider silk after it has coagulated.

6

Experiment

The DNA plasmid arrived in a filter paper and was extracted by incubating it at room temperature with water for 2 minutes and centrifuging it at maximum speed for 10 minutes. As the water flowed through the filter paper it collected the DNA at the bottom of the centrifuge tube. The filter paper was discarded and part of the DNA was used to transform E.coli cells in a solid culture. The cells grew overnight and were used in a miniprep to amplify the amount of DNA plasmids available for experimentation. The concentration of amplified plasmids was determined via a spectrophotometer and then used in a DNA double digest and ligation with NgoMIV and BsaI to create a sample of DNA without the TC motif.

If the DNA had been ligated properly, the NgoMIV cut site should have been removed while the BsaI cut site was maintained. To test whether the TC motif was properly removed, separate DNA digests were done with the ligated DNA and BsaI and NgoMIV. The samples were then separated by gel electrophoresis (Figure 4). Since DNA plasmids travel slower when they have been digested, the expected results for a successful removal of the TC motif would have been band 4A traveling the furthest, band 4B traveling a similar distance, and band 4C and 4D traveling a noticeably shorter distance than the others. Instead, band 4A was observed to travel the furthest while bands 4B, 4C, and 4D traveled approximately the same distance (Figure 4). From this it can be concluded that the TC motif was not properly removed from the DNA plasmids. Due to time constraints I was unable to repeat the digest and try to obtain plasmids without the TC motif.

7

Figure 4. Gel electrophoresis of ligated and undigested DNA with NgoMIV and BsaI. From left to right, the samples are a ladder and 20 µl of the original, undigested DNA with the TC motif, the ligated DNA from the double digest with NgoMIV, the ligated DNA from the double digest with BsaI, and the original, undigested DNA with BsaI.

E.coli cells were transformed with the amplified DNA plasmids and grown in a solid culture overnight. They were then induced with IPTG and allowed another day to produce the spidroins, after which they were collected and lysed. Part of the whole-cell lysate was reserved while the other part was purified via Nickel-NTA purification. However, the results of the proteins being analyzed via mass-spectroscopy were completely unexpected and suggested that the proteins might not have been properly purified.

1ml samples of the whole-cell lysate and purified proteins were placed in 27 G and 30 G syringes with varying needle diameters and extruded at different speeds into a coagulation bath of isopropanol. Ultimately, spider silk was produced from the whole cell lysate in a 27 G syringe with a tip of 0.21 mm diameter at an extrusion speed of 15 µl/min (Figure 5). It is possible that the purified proteins were not eluded properly or diluted so much that they could not properly form strands of spider silk.

8

Figure 5. Spider silk produced from whole-cell lysate in an isopropanol coagulation bath.

Before binding the Au nanoparticles to the spider silk proteins, the Au nanoparticles were sonicated for 15 minutes to undo any aggregation. A small hole was drilled into the side of a syringe where a tube was placed connecting it to a nitrogen gas tank. Due to the success of the lysate in producing spider silk, a 3 ml sample of the lysate was mixed in the syringe with 1 ml of Au nanoparticle solution and nitrogen gas was introduced via the hole in the syringe. Nitrogen gas was added since it is chemically inert and by purging the oxygen from the syringe the Au nanoparticles should have oxidized less and been more capable of binding to the proteins. However, the protein and Au nanoparticle solution was not able to produce any strands of spider silk, and due to time constraints I was unable to pursue the issue any further.

9

Moving Forward

It will be extremely important to properly purify the proteins and obtain them in a high concentration. This should overcome the initial issue of the purified proteins not producing any silk compared to the lystate. Also, more research will have to be done towards finding the optimal ratio of Au nanoparticles to proteins and whether the Au nanoparticles should be a different size. Something else to consider is whether the protein’s design should be changed to have multiple TC motifs or if the TC motif should be included at all. Other options to help the proteins bind to Au nanoparticles might be to replace certain residues with cysteines or to include long sequences with only cysteines. With these considerations and others in mind, I am optimistic about retaking this project in the future and producing synthetic spider silk that conducts electricity!

10

References

1. Vienneau-Hathaway, J.M., Brassfield, E.R., Lane, A.K. et al. Duplication and concerted evolution of MiSp-encoding genes underlie the material properties of minor ampullate silks of cobweb weaving spiders. BMC Evol Biol 17, 78 (2017). https://doi.org/10.1186/s12862-017-0927-x.

2. Deptuch, T., & Dams-Kozlowska, H. (2017). Silk Materials Functionalized via Genetic Engineering for Biomedical Applications. Materials, 10(12), 1417. https://doi.org/10.3390/ma10121417.

3. Li, C., Liu, J., & Yang, J. (n.d.). Spidroin Engineering with Chromoprotein and Natural Dye. https://2019.igem.org/Team:GreatBay_SZ.

4. Reed, A. M. W. (n.d.). The Genetically Encodable Oriented Adsorption of Proteins onto Gold Nanoparticles [Doctoral dissertation]. Digital Georgetown. https://repository.library.georgetown.edu/handle/10822/557940.

5. Rising, A., Johansson, J. Toward spinning artificial spider silk. Nat Chem Biol 11, 309–315 (2015). https://doi.org/10.1038/nchembio.1789.

6. Langmuir 2010, 26, 24, 18945–18950 Publication Date:November 29, 2010 https://doi.org/10.1021/la1035135.

7. Madurga, R., Gañán-Calvo, A. M., Plaza, G. R., Guinea, G. V., Elices, M., & Pérez-Rigueiro, J. (2017). Production of High Performance Bioinspired Silk

Fibers by Straining Flow Spinning. Biomacromolecules, 18(4), 1127-1133. https://doi.org/10.1021/acs.biomac.6b01757.

8. Andersson, M., Jia, Q., Abella, A., Lee, X.-Y., Landreh, M., Purhonen, P., Hebert, H., Tenje, M., Robinson, C. V., Meng, Q., Plaza, G. R., Johansson, J., & Rising, A. (2017). Biomimetic spinning of artificial spider silk from a chimeric minispidroin. Nature Chemical Biology, 13(3), 262-264. https://doi.org/10.1038/nchembio.2269.

9. Love, J. C., Estroff, L. A., Kriebel, J. K., Nuzzo, R. G., & Whitesides, G. M. (2005). Self-Assembled Monolayers of Thiolates on Metals as a Form of Nanotechnology. Chemical Reviews, 105(4), 1103-1170. https://doi.org/10.1021/cr0300789

10. Theo Walker. 2014. Open Syringe Pump.

https://github.com/manimino/OpenSyringePump.

11